PTO Drive Pellet Mill

Small scale power taken off tractor biomass pellet processing equipment is also called PTO pellet mill, which is a small type wood pellet mill machine with small capacity. This PTO wood pellet mill has two types, D-type and R-type.

Send InquirySmall scale power taken off tractor biomass pellet processing equipment is also called PTO pellet mill, which is a small type wood pellet mill machine with small capacity. This PTO wood pellet mill has two types, D-type and R-type. The two type flat die PTO drive pellet mill are all good at making wood pellets. Relatively speaking, the yield of D-type is less than R-type. So it is more suitable for processing soft wood raw materials ( like saw dust ). Besides, the investment is lower. R-type PTO pellet mill is more suitable for harder wood raw materials ( like Oak wood ). From the aspect of structure, the roller of D-type PTO wood pellet mill is fixed on the upper machine and the die rotates with the main shaft. R-type is contrary to D-type, the die of R-type is fixed while the roller rotates.

Advantages of PTO drive pellet mill

The PTO drive pellet mill is easy to operate and move.

PTO drive pellet mill takes small place to put.

Small volume makes the saw dust pellet making machine easy to maintain and change spare parts.

The PTO drive pellet mill is cost-effective for the low price.

Flat die wood pellet machine is with CE certification, which makes sure the stable running and high performance.

The wood granulator consume lower energy producing more profits.

The end products are of high density and hardness.

Technical Parameter

|

Type |

Power |

Capacity(kg/h) |

Dimension(mm) |

Weight(kg) |

|

PL-120 |

8HP |

60-100 |

730*320*670 |

135 |

|

PL-120B |

3KW |

60-100 |

750*310*620 |

100 |

|

PL-150 |

8HP |

100-200 |

760*430*710 |

150 |

|

PL-150B |

4KW |

150-220 |

770*340*680 |

115 |

|

PL-200 |

15HP |

220-350 |

1180*560*1020 |

360 |

|

PL-200B |

7.5KW |

200-300 |

1000*430*950 |

210 |

|

PL-230 |

11KW |

300-400 |

1150*500*970 |

320 |

|

PL-260 |

15KW |

400-600 |

1200*500*1030 |

370 |

|

PL-300 |

22KW |

600-800 |

1320*530*1070 |

480 |

There are two major parts of the PTO drive pellet mill, roller and pellet die. They are the key parts during the biomass pellet processing and they decide the quality of pellets.

PTO pellet mill roller with a cylinder shape is large which increases the contact area between roller and materials, that improves the yield, rate of pellet making, and pellet density. The pellet die is a round plate with many holes, and the materials are pressed by the roller into those pellet die holes forming cylindrical rods.

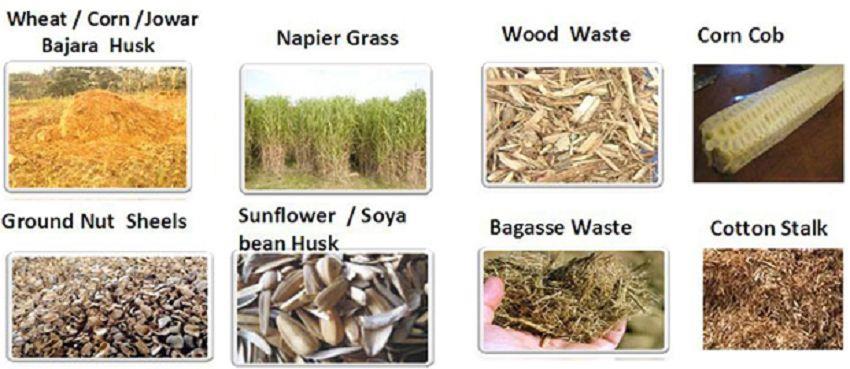

Suitable Raw Material

●Wood pellet mill can press any biomass waste, wood waste, sawdust, straw, stalk, shell, such as peanut shell, coconut shell, baggage, grass, hay, alfalfa into pellets as fuel and feed.

●Wood pellet mill is multifunctional, can press any grain such as corn, wheat, bean, soybean into pellets as food for animal.

●Wood pellet mill can also press pellet from animal manure as organics fertilizer.

Attentions of operation

●Be sure to stop the pellet mill when the service man maintain the pellet mill, and cut off all the electricity supply and hang on the warning sign, to prevent human error accident from unexpected operation of machine.

●The operators should read the instructions carefully and have good understanding of the character of the homemade pellet mill, structure and application method. Stall and debug, use and maintain the pellet mill according to regulations.

●Special lubricant should be added into the bearing of compression rollers of the pellet mill after every 12 hours of the operation of the pellet mill.

●Please do cut off the electricity when rotating the compression rollers by hand. Please do not touch the rotating compression rollers and flat die by hand or other objects.

●The clearance between the compression rollers and the flat die should below 10.mm, too small the clearance give rise to over wear resistance between compression rollers and flat die, even the damage of the whole pellet mill.

●When the temperature of the homemade pellet mill is below 10℃, the lubricant of the pellet mill are easy to freeze. Please warm the homemade pellet mill to 10℃ and start the machine.

About Ainuok

Anyang Ainuok After 10 years development, now our company becomes an independent economic entity with the integration of science, engineering and trading department. our products and are widely accepted in both domestic and now open the world market, service to more than 100 countries, such as England, Russia, Sweden, Poland, Iran, Sudan, South Malaysia, Indonesia, Vietnam, etc.

Offering 4 Production Line for Pellet Production

●Biomass Wood Pellet Production Plant

●Small Wood Pellet Production Plant

●Animal feed Pellet Production Plant

●Wood sawdust charcoal briquette Plant

Supplying Crusher ,Dryer,Mixer for prepare mushroom substrate for mushroom cultivation.

Offering Bagging machine for filling bag for growing mushroom.

Guiding for Recycle processing waste mushroom substrate ,into Pellets .make waste into value.

If you need any support in Mushroom cultivation Equipment ,and Pellet Production plant ,Charcoal Briquette production plant .,Welcome to Contact us .

Hot Tags: PTO drive pellet mill, China, manufacturers, factory, cheap, low price, made in China

Previous: Diesel Pellet Mill

Next: Electric Pellet Mill