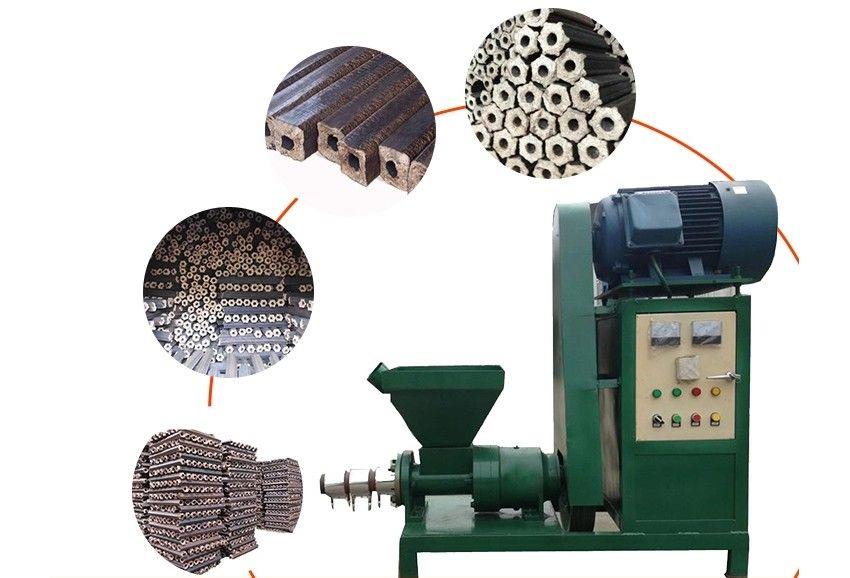

Biomass Briquette Machine

Biomass briquette machine shows the features of high capacity, low energy consumption, compact and durable.

Send InquiryBiomass briquette machine shows the features of high capacity, low energy consumption, compact and durable. Many performance data such as capacity, wood briquettes density, electricity consumption and wearable degree has reached advanced level. Charcoal briquette machine can be used as charcoal powder briquette machine by replacement of some spare parts. The out diameter of finished briquettes is 50mm/80mm.

Prospect

Due to the rapid increase in the need of energy source, more people start to become interested in Biomass Briquette business. Biomass Briquette are renewable, Eco-friendly Energy especially for agricultural countries.Biomass Briquette investment is a best project to generate revenue from agro-forestry waste and to produce Green Energy to save the global environment. The awareness of using Eco-friendly & Non-conventional Bio-coal / Bio-fuel is increasing day-to-day due to the increasing of the conventional fuel cost. This plant can make charcoal stick of different diameter and different shape from biomass and agro-forest waste. Raw Material to make Biomass Briquette:Any type of Agro-Forestry waste can be used.

Raw Material

●Biomass wastes, such as sawdust,rice husks,coffee husks,rice straw, wheat straw,etc.

●Material required: Moisture 8%-12%,size3-5mm

●If moisture>12% may need dryer,We have air flow dryer and drum dryer.

●If material size >5mm will need hammer mill or wood crusher.

●When begin to work,the heating circle heat the machine,then wood briqutte machine can press sawdust without any binder, sawdust pressed by high temperature and high pressure , then the screw press sawdust forward,extrusion into a rod-shaped solid rod with center hole.

Working Principle

●Briquetting is a process that biomass is compressed under high pressure and high temperature. The machine uses a large screw to grind,compress and extrude the biomass into briquettes.

●The self bonding of biomass to form a briquette involves the thermo-plastic flow of the biomass. The natural lining content in biomass is liberated under high pressure and temperature. Lignin serves as the glue in the briquetting process, binds the particles of wood together, thus binding,compressing the biomass to form into high density briquettes.

●During this process, no binder need to be used. So the output briquette is a type of clean and green fuel that is ideal for use in furnaces, boilers and open fires.

Characteristic

●No binder or noxious chemical need to use.

●The humidity of the raw materials is controlled in 8-12%.

●Using the advanced Hot air drying system with the perfect performance.

●After the processing of High temperature, purification, smoke removing, the carbonizing equipment transforms the semi-finished bio-fuel briquette into a smoke-free, tasteless, non-toxic cleaning carbon.

Technical Parameter

|

Model |

BC-50 |

BC-80 |

|

Diameter |

50mm |

80mm |

|

Capacity |

200-250 kg/h |

250-300kg/h |

|

Power |

18.5kw |

22kw |

|

Weight |

550 kg |

700kg |

|

Out size |

1800*600*1600mm |

1800*700*1600mm |

|

Moisture |

5%-12% |

5%-12% |

Final Product

Application for Charcoal Briquette

●Used as bio fuels for boiler

●For Stove, Home heating

●Used BBQ charcoal for Barbecue

●Fuels for Europe country Fireplace etc.

Note

●MOQ: 1SET

●Payment Terms: T/T,L/C,Western Union,Alibaba,Money Gram etc.

●Delivery Time: within 7-10 days after receipt of deposit

●Warranty Time: 1year

●CE Certification

Hot Tags: biomass briquette machine, China, manufacturers, factory, cheap, low price, made in China

Previous: Briquetting Press