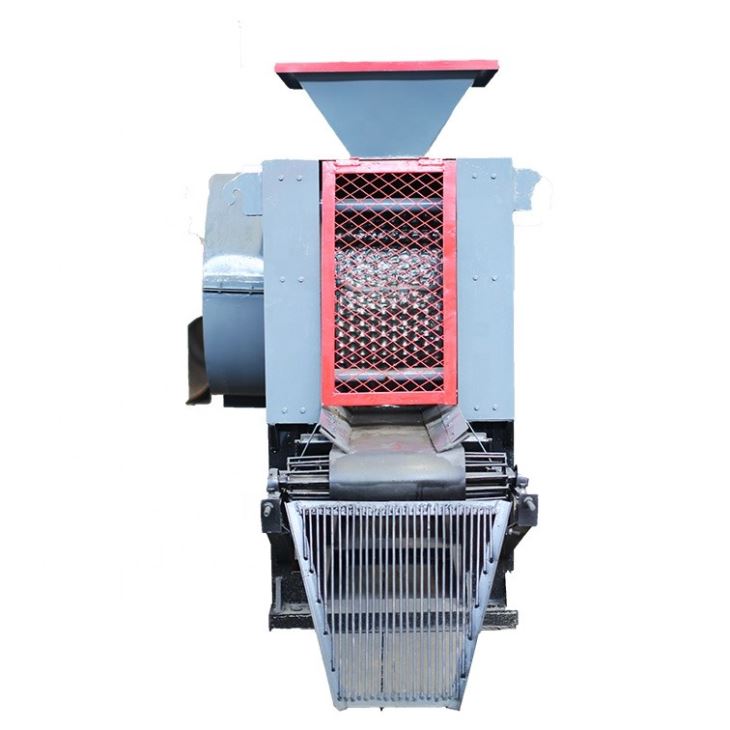

Coal Briquette Press

Coal Briquette Press can press charcoal powder, charcoal dust, coal powder, etc into ball or pillow-shaped charcoal. The diameter of briquettes can be 20-60 mm.

Send InquiryCoal Briquette Press can press charcoal powder, charcoal dust, coal powder, etc into ball or pillow-shaped charcoal. The diameter of briquettes can be 20-60 mm.

Two rollers, The final charcoal briquettes with high density are easily burnt, no odor and no smoke.

Features

●The briquettes produced by our machine are smokeless, smelless, because we have the high technology liquid binder recipe.

●The service live of charcoal ball briquette making machine is prolonged, especially the wear-resistant spare parts.

●The machine is easy operation, easy maintain.

●This machine is energy saving, can save electricity of 60%, save labors of 2-3 person. Also it is environment protect, it can totally compress the charcoal powder into coal charcoal briquettes, less residue.

●The pressure is highly increased because we have not only the four roller type coal charcoal ball briquette machine, also we have hydraulic type.

Technical Parameter

|

Model |

Roller Dia(mm) |

Roller Width |

Capacity (t/h) |

Power (kw) |

Dimension (m) |

|

BL-290 |

290 mm |

200 mm |

1-3 |

5.5 |

1.6*1.2*4 |

|

BL-360 |

360 mm |

250 mm |

4-6 |

7.5 |

2.1*1.3*1.76 |

|

BL-400 |

430 mm |

280 mm |

6-8 |

11 |

2.3*1.53*1.9 |

|

BL-500 |

500 mm |

300 mm |

8-10 |

15 |

2.6*1.75*2.1 |

|

BL-650 |

650 mm |

336 mm |

10-15 |

22 |

3.42*2*2.2 |

|

BL-750 |

750 mm |

400 mm |

15-20 |

37 |

3.7*2.55*2.6 |

|

BL-850 |

850 mm |

500 mm |

20-25 |

45 |

3.9*2.6*2.7 |

|

BL-1000 |

1000 mm |

650 mm |

25-30 |

55 |

4*2.8*2.8 |

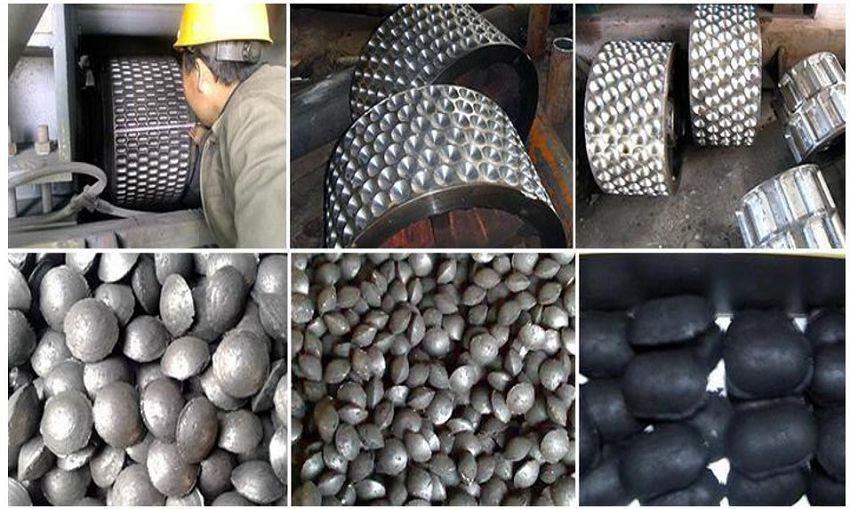

Finished Products

Square, ball egg-shaped, round, oval, and column, strip-type, elliptic type,pillow type and other special shapes by customizing the matching molds. Usually 20-60mm. coal briquette press machine for sale / coal briquette press machine price/ coal briquette press machine suppliers suppliers mine coal briquette making machine. We can supply you any types of the final product you customize.

●Size: It's better to be less than 3mm. If not, crusher is needed.

●Uniformity: Mixer may be needed to make materials homogeneous.

●Moisture content: 9-15%. If higher than this, rotary dryer is needed.

●Advantages of Coal Briquette

Less smoke, Non-pollution, large capacity, easy operation, less consumption.

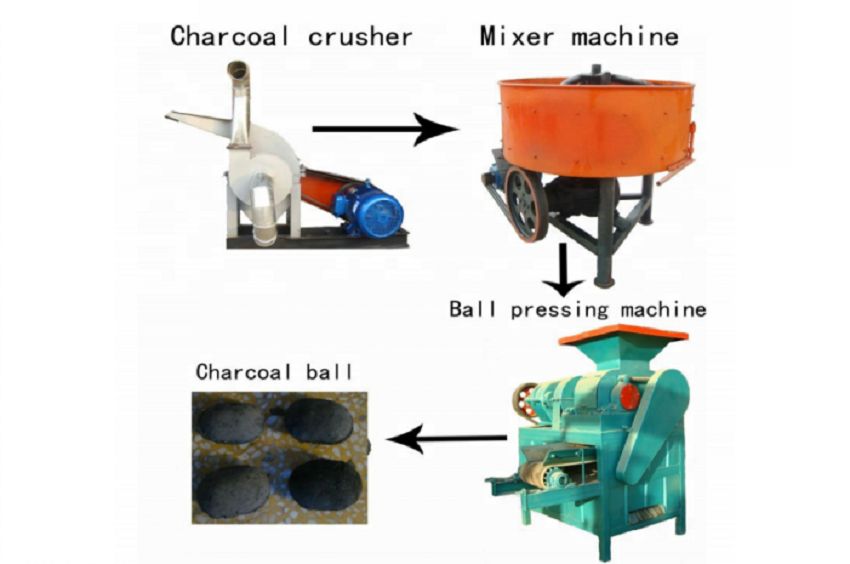

Processing

Raw materials---crushing---mixing---screening---briquetting---final products

For different materials and different production information, our technician will design the special suitable line for you.

Structure

1. The feeding part, is used to feed material so that the material can feed to roller evenly ,it is drive by Spiral comprises electromagnetic motor.

2. The transmission part, main transmission system is: Motor - triangle belt - reducer - Open Gear - roll.

3. Forming part, mainly refers to the part of the host machine, its core part is roller.

Different Rollers

The material of roller is: 65Mn or 9Cr2Mo.

a. common charcoal making machine south Africa:the roller material is 65Mn.

b. hydraulic charcoal making machine south Africa: the roller material is 9Cr2Mo. Both is wear resisting material.

It can service 10-12months(depends on your used raw materials)

FAQ

What materials can i use?

Charcoal powder / charcoal dust: raw material powder, silicomanganese alloy, etc.

Coal: Coal powder, middle coal, slime peat, coke powder, lignite etc.

Other material: fireproof material, desulfurization gypsum, dolomite etc.

Which shape does your machine produce?

The final shape can be customized by your request.But it is ball or pillow shape.

Do i need to mix binder to press?

Yes, you can mix binder or combustion improver. But the binder depends on your material.

The most common binder is starch. It will not influence briquette quality.

Hot Tags: coal briquette press, China, manufacturers, factory, cheap, low price, made in China

Previous: No Information

Next: Ball Press Machine